And the rear shock for that matter

What goes on inside your fork and shock? Discover the whole story as we delve into the inner workings of your suspension.

>>> How to set up mountain bike suspension

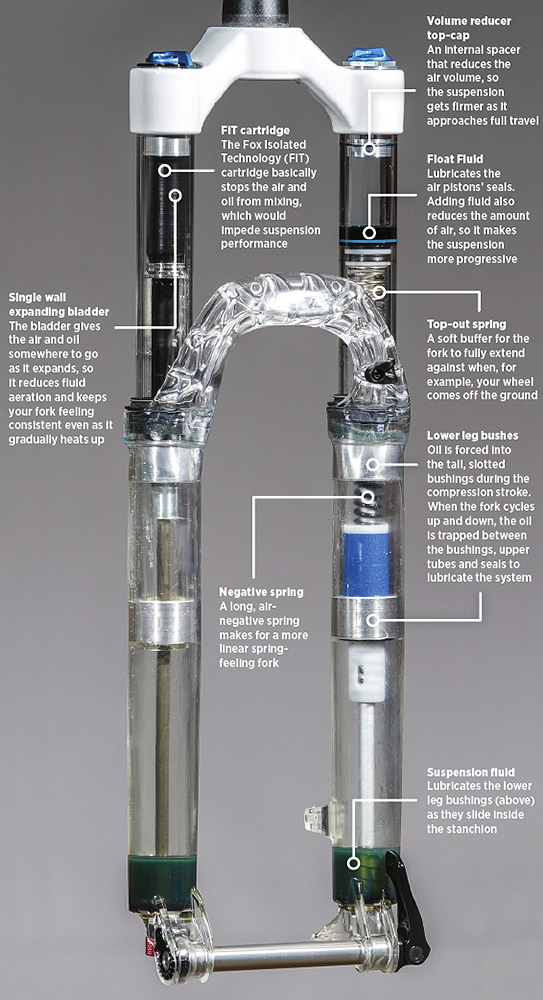

Suspension fork

Damping cartridge

The cartridge basically stops the air and oil from mixing, which would impede suspension performance.

Single wall expanding bladder

The bladder gives the air and oil somewhere to go as it expands, so it reduces fluid aeration and keeps your fork feeling consistent even as it heats up

Wiper seal

Keeps the oil in and mud out.

Foam ring

Saturated in lube, the ring lubricates the stanchions as they move

Volume reducer top cap

An internal volume spacer which reduces the air volume, so the suspension gets firmer as it approaches full travel.

Top-out spring

A soft buffer for the fork to fully extend against when, for example, your wheel comes off the ground.

Lower leg bushes

Oil is forced into the tall, slotted bushings during the compression stroke. When the fork cycles up and down, the oil is trapped between the bushings, upper tubes and seals to lubricate the system.

Suspension fluid

Lubricates the air pistons’ seals — adding fluid also reduces the amount of air in there, so it makes the suspension slightly more progressive

Negative spring

A long, air-negative spring makes for a more linear spring feeling fork.

Rear shock

>>> Suspension setup masterclass with Mojo

Air volume reducer

Tinker with this to change your air spring curve. Larger volume spacers make the air spring rate progressive; smaller spacers make for a more linear coil-spring feel.

Air sleeve

Also called the air can, the sleeve is pressurised when you put air into the shock.

Positive air chamber

Pressurised air acts as an easily adjustable spring.

Negative air pressure

Pressurised air preloads the shock into its travel, so there’s less effort needed to get it moving at the start of the stroke – it basically makes the shock feel more sensitive.

Air sleeve transfer port

Lets air move between the positive and negative chambers so the shock can automatically balance its spring rate

Piston assembly

Damping is created by shims that flex open, allowing oil to flow across the piston on the rebound stroke.

Suspension fluid

Provides the fluid for damping and lubricates the shock internals.

Body tube

Stores the fluid and houses the piston and its valves. The internal seals inside the air sleeve slide against the tube.