Rites of passage, lessons learned, call them what you will, try to not do these please

A job done badly is worse than just leaving it well alone. Here are ten of the best/worst cardinal sins of the bike workshop bodgers.

>>> All the jobs you’ve put off that you now have no excuse to avoid

1. Overtightening bolts

There is no need to gorilla-heave on your Allen key when doing up most of the bolts on your bike. Almost every bolt on your bike is supposed to be either 5Nm or 6Nm tight. Tightening bolts up beyond their designed force will lead to parts getting damaged and also annoying clicks and creaks.

2. The wrong grease

We’ve all been there; “some grease is better than no grease!” Er, nope. Using the wrong grease can be a very bad thing. Use normal grease on a carbon frame and you’ll potentially have to bin the whole frame. Use the wrong sort of grease during a guerilla suspension fork ‘service’ and you’ll end up with a sticky non-moving fork, or worse.

3. Not chain lube

Similar to above but worth highlighting on its own. Using something that isn’t specific bike oil for lubing your chain. Engine oil, chainsaw oil, sewing machine oil, 3-in-1, WD40… you name it. Avoiding proper chain lube because it’s “too expensive” is the worst money-saving thing you can do. It will cost you a whole new drivetrain.

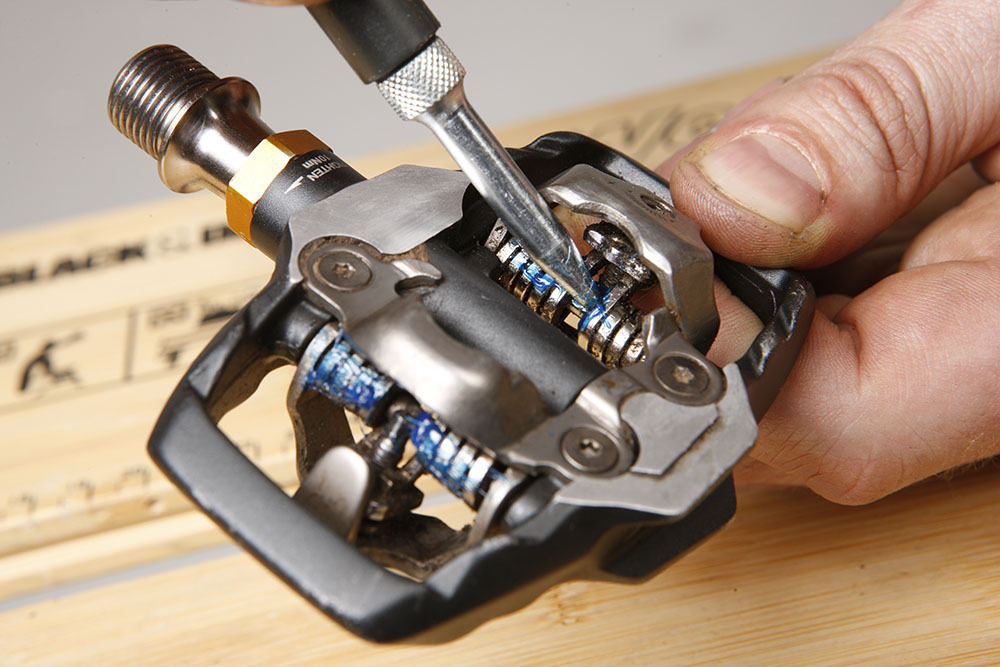

4. Not (re)greasing pedals

We don’t see very many seized-in seatposts these days for some reason (dropper posts? carbon frames?) but one thing that’s still prevalent is seized-in pedals. Pedals have a hard life. They sit way down low and get all the wet filth thrown at them. They never get a second thought… until it’s too late. At which point they reveal themselves to be bonded to the cranks. This leads to the classic workshop injury: punching the chainring.

5. Not tyre lever

Spoons, knives, screwdrivers… Using anything that isn’t a tyre lever for getting a tyre on or off a wheel rim. At best, you’ll puncture the inner tube. At worst, you’ll permanently wreck your wheel rim.

6. Forgetting about lefthand threads

One of your pedals is weird. It does not undo like a normal thing. It uncrews clockwise. In other words, it has a lefthand thread. Not realising or remembering this results, again, with the classic workshop injury: punching the chainring.

7. Rejoining a chain incorrectly

Whether it’s unwisely reusing a Shimano chainpin, or simply doing a really bad job of rejoining any chain, assuming that it will be fine is a big mistake. A mistake you will realise as you headbutt your stem as your chain gives up the ghost. Several miles from civilsation.

8. Trueing a wheel with no clue

If you’re not sure how to true a wheel, don’t. And if you really, really must have a go, please don’t think that you can get away with only adjusting the spokes on one side of the wheel. It doesn’t work like that. Dabbling with wheel trueing is easily the riskiest – and potentially most expensive – ‘repair’ you can attempt.

9. Using an adjustable spanner

Besides that old set of Imperial standard Allen keys you have lurking in your tool drawers somewhere (for working on an American BMX you no longer even own), the adjustable spanner is the single most dangerous tool in your workshop. It just ruins everything it touches. Spoke nipples rounded. Fork top caps permanently damaged. Crank arms and pedal axles badly scored.

10. Not cable cutters

Using the jaws of a pair of pliers for trimming down inner cables. Just don’t. Better to just loop-up the excess cable, tape it in place and then get hold of some proper cable cutters.