CARBON YES OR NO?

CARBON YES OR NO?

My wife and I both ride Marin bikes (MV and Rift Zone) that we bought about four years ago, and soon after buying, I upgraded the bars and seatposts to Easton carbon versions. We are planning a trip up to Scotland this summer for some serious biking on Harris and Skye so I feel that we should replace the bars and seatposts prior to the trip.

Question is, should we buy carbon, circa £80 an item, or alloy versions, at £30 an item?

We are not into racing and although I always buy good quality components as and when they need replacing, is there really any advantage in staying with carbon bars and seatstems other than they look great?

All the best

Richard Baillon, Nottinghamshire

Carbon handlebars and seatposts do offer a performance advantage over their aluminium counterparts as they are generally lighter, stronger and most would argue “better looking”.

The other bonus feature that is often overlooked is that of vibration reduction which reduces rider fatigue and improves comfort.

While it is possible to manipulate aluminium tube by butting and forming, thus modifying the level of flex the tube will withstand, the amount of manipulation you can carry out with aluminium is quite limited when compared to the wall thickness and sectional changes that are possible with carbon composites. Easton’s own sales literature shows how much better its carbon bars and posts perform on maximum load, tensile strength and fatigue life when compared to its own aluminium equivalents. So, apart from the cost disadvantage with carbon bars and posts it looks like carbon beats aluminium hands down? ….er, no! Clinical lab tests on new components produce useful data but don’t replicate real-world conditions or scenarios. Unless you are the most careful of riders, your handlebars and seatposts will quickly pick up scuffs and grazes. These surface imperfections affect the structural integrity of the components and the more serious marks could be marking the point at which a component fails completely.

For the most part, structural problems with aluminium products will be linked directly to externally visible defects or marks. With carbon composites, however, impacts may cause sub-surface problems that are not visible externally, lulling the owner into thinking their bars and seatpost are in A1 condition despite bailing on that last back flip attempt!

If you have a big crash and are unsure about the condition of your bars or post — change them. Or if they’ve been used well for a few seasons — change them.

I know throwing away a pair of £80 handlebars that ‘might be OK’ is hard, but it’s definitely preferable to trying to go down Glentress’s Spooky wood trail using your chest to steer.

Easton composite bars and posts are very good and I’ve used them on my own bikes, including DH race bikes, with no problems, but given the fact that the weight advantage is minimal and that your planned trip may place you a long way from a bike shop, I feel fitting the less exotic aluminium bars and post would be the way to go.

DUAL CONTROL

I have noticed that in general you are not big fans of Shimano Dual Control. In fact you recently wrote that you predict it to be heading the same way as Biopace and U Brakes! As a huge fan of the integrated brake and gear levers I find this really hard to understand. Do you feel that they are not user-friendly enough, or is it to do with performance? Having been a dedicated mountain biker for 18 years now I can honestly say I think it’s one of the best things to come out of the Shimano stable! Have I missed something?

Thanks for all the pages of inspiration.

Robin, email

In typical Shimano style, all the Dual Control levers are fantastically well built, shift smoothly, stop you as well as their separate brake levers and last longer than anybody else’s kit.

Sounds perfect? Wrong! I admit there’s a place for them with the arse-in-the-air, flat-handlebar rider, who spends most of his time on tarmac, forestry roads or manicured trail.

But as soon as you start to tackle technical terrain, from which most of us get our fix, the dual control becomes at best irritating or, if it’s really technical, going on infuriating.

Why this annoyance? The best bits of trail should force you into using your full repertoire of bike handling skills — wheelie, manual, bunny hop, drift and endo. All this manoeuvring requires precise interaction between rider and bike at two specific points, pedals and more importantly handlebars. I’ll wager whether you’re a pro of Steve Peat’s stature or a lowly editor like Kitch, you will be covering the brake levers and exerting vertical force on them as you move the bike around and if those levers don’t feel solid or give you a fixed position

then the finesse disappears from your riding. It’s even more off-putting if you get an unexpected gear shift while lofting the front end. If you think I’m overstating the issue — and you’re feeling brave — try riding doing a wheelie, manual or bunny hop with your brake lever clamps loose and free to rotate around the bars — the brakes will still work but I bet you won’t want to try it a second time! Disclaimer: I accept no responsibility for the gravel rash that afflicts those of you daft enough to try this.

The final nails in the coffin lid of Dual Control are that it is more costly, not much lighter and prevents independent set-up of brake and gear shift levers.

HEADSETS

I have a problem with my GT i-Drive 0.0 headset bearing and would be most grateful if you could offer some advice. I have had my bike now for about three years and noticed that the headset was becoming stiff. I diagnosed that the headset bearings were at fault. Imagine my disgust after dismantling the headset only to find a non-sealed unit fitted. Despite my best efforts, I have been unable to find a sealed cartridge unit to fit the headset, and all I have been able to do over the past year is regrease the bearings every three or four rides.

Do you have any suggestions as to what I can do? I would really like to fit a sealed cartridge unit but to date I have been unable to find one that will fit the headset as it does not seem to be either 1 1/8in or 1 1/2in diameter.

John Nellis, email

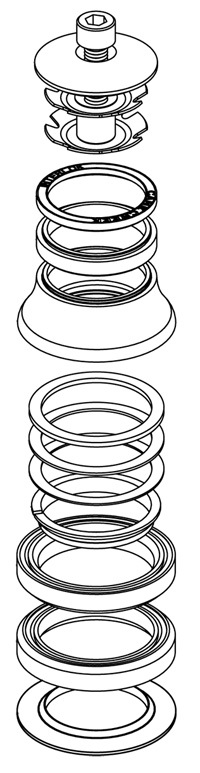

The headset used on your GT is the integrated type. There is no cup pressed into the frame to hold the bearing; it sits directly in the frame against a turned or machined face. With no cups to press in, assembly is very quick and there is a worthwhile weight saving to be had. The downside is that smoothness and lifespan are dependent on the preparation of the frame’s bearing seats being spot-on. As with the more traditional cupped headsets, integrated is available to suit 1” and 1 1/8” steerers. Unlike traditional headsets, where there is a single internationally set dimension for the press fit cups, integrated bearings are available in several outer diameter options even where the inner diameter is set for 1 1/8in. The change in OD is due to the different type of Angular Contact Bearings (ACB) that can be spec’d, ie, 36×36 degree, 36×45 degree and 45×45 degree. The bearing seat machined into the head tube of each frame is matched to whichever bearing has been chosen, meaning you have to stick to the size of bearing originally spec’d by the manufacturer — no real problem once you know the size, and in your GT’s case that should be a 36×45 ACB setup. The integrated style of headset has had a mixed response from the mountain bike market but has become the standard for road bikes. FSA and Cane Creek are the two big producers of these headsets and a sealed bearing offering from one of these two can be had for around the £20 mark.